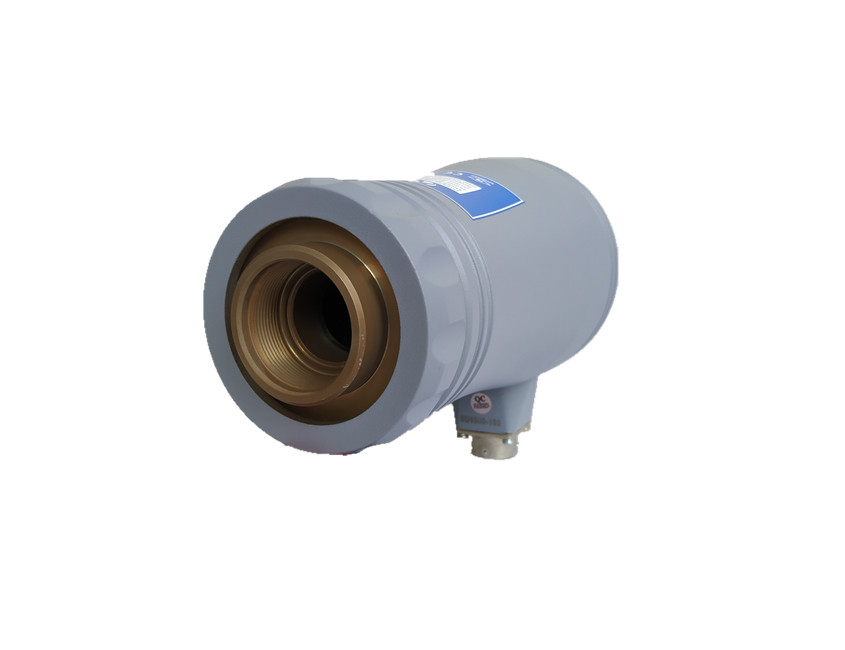

Platinum-Rhodium Thermocouple

Platinum-Rhodium Thermocouples, also known as Precious Metal Thermocouples, serve as temperature sensors in industrial applications. They are typically used in conjunction with temperature transmitters, regulators, and display instruments to form process control systems. These thermocouples are designed to directly measure or control temperatures ranging from 0 to 1800°C in various industrial processes, including fluids, steam, gas media, and solid surfaces.

Key Features:

- High Accuracy: Excellent stability for precise temperature measurement.

- High-Temperature Resistance: Long-term use at 1600°C+ (Type B up to 1800°C).

- Oxidation Resistance: Pt-Rh alloys resist oxidation, ensuring long service life.

- Low Drift: Maintains accuracy even after prolonged use.

- Material: Precious metal (high stability & accuracy)

- Application: High-temperature process control (e.g., furnaces, labs, metallurgy)

- Compatibility: Integrated with transmitters, controllers, and monitoring systems.

Common Types

Based on their composition, the three standard types are:

- Type S (PtRh10-Pt): Platinum-10% Rhodium vs. Platinum, range 0–1600°C

- Type R (PtRh13-Pt): Platinum-13% Rhodium vs. Platinum, range 0–1600°C

- Type B (PtRh30-PtRh6): Platinum-30% Rhodium vs. Platinum-6% Rhodium, range 0–1800°C

Supporting Equipment

Often integrated with temperature transmitters, controllers, and display instruments to form automated control systems for precise thermal regulation.

Platinum-Rhodium Thermocouple Key Technical Specifications

- Electrical Connection: M20×1.5, NPT½

- Accuracy Class: I, II

- Protection Rating: IP65

- Thermocouple Wire Diameter: Φ0.5mm

- Nominal Pressure: Atmospheric pressure

Thermocouple (Resistance) Installation Guidelines:

To ensure adequate heat exchange between the measuring end of the thermoresistor and the measured medium, the measurement point location should be selected appropriately, and installation should be avoided near valves, elbows, and dead corners of pipes and equipment.

Insertion Depth Requirements: The measuring end should have sufficient insertion depth, with the measuring end of the protective sheath extending beyond the pipeline centerline by 5–10 mm.

Insertion Direction Requirements: Ensure adequate contact between the temperature-sensing element and the medium. It is best to insert the thermocouple facing the direction of the measured medium flow or install it vertically along the pipeline.