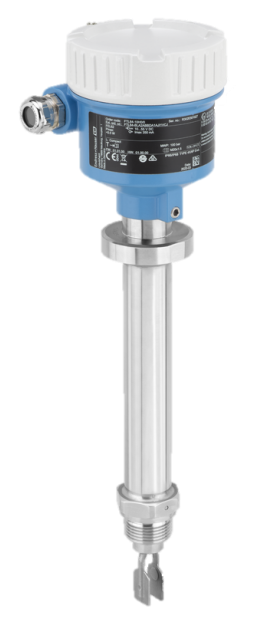

Radar Level Sensor Micropilot FMR60B In Stock

Model: FMR60B-NCBAEMHHGAA3VEJD+AAJAKBLAPAZ1 (Stock Qty; 17units)

Model: FMR60B-NCBAEMHHGAA3VEJD+AAJAKBPAZ1 (Stock Qty; 12units)

Brand: Endress + Hauser

Configuration:

| Characteristic | Value | Description | TSP-No. | Marking Mat. |

| Approval: | NC | NEPSI Ex db IIC T6 Ga/Gb | – | – |

| Output: | BA | 2-wire 4-20mA HART | – | – |

| Display; Operation: | E | Graphic display with touch control | – | – |

| Housing; Material: | M | Dual compartment L-shape; Alu, coated | – | – |

| Electrical Connection: | H | Thread NPT1/2, IP66/68 NEMA Type 4X/6P | – | – |

| Application: | H | Process temperature -40…130°C/-40…266°F | – | – |

| Antenna: | GA | Drip-off, PTFE 50mm/2″ | – | – |

| Process Connection, Sealing Surface: | A3 | Thread ASME B1.20.1, NPT | – | – |

| Process Connection: | VEJ | MNPT1-1/2, 316L | ||

| Seal: | D | FKM Viton GLT | – | – |

| >Operation Language Display: | AA | English | – | – |

| >>Test, Certificate, Declaration: | JA | Inspection certificate 3.1, EN10204 (material certificate wetted metallic parts) | – | – |

| KB | Pressure test, internal procedure, test report | – | – | |

| >>Additional Approval: | LA | SIL | – | – |

| >>Accessory Enclosed: | PA | Weather protection cover, 316L | – | – |

| >>Marking: | Z1 | Tagging (TAG), see additional spec. | – | – |

Specification:

| Measuring principle | Level radar |

| Characteristic / Application | For simple continuous non-contact level measurements in liquids, pastes, and slurries; Not influenced by changing media,temperature differences, gas phases or steam; For vessels with many internals |

| Specialities | Heartbeat Technology; SIL 2 according to IEC 61508; Bluetooth® commissioning; Operation and maintenance with SmartBlue App; HistoROM; RFID TAG for easy identification |

| Supply / Communication | 2-wire (HART/ PROFIBUS PA) PROFINET with Ethernet-APL Bluetooth® wireless technology |

| Frequency | W-Band (~80 GHz) |

| Accuracy | +/-1 mm (0.04 in) |

| Ambient temperature | -40 … +85 °C (-40 … +185 °F) |

| Process temperature | -40 … +200 °C (-40 … +392 °F) |

| Process pressure / max. overpressure limit | Vacuum…20 bar (290 psi) |

| Main wetted parts | PVDF, PTFE or PEEK |

| Process connection | Thread: G3/4″ and 1-1/2″, MNPT 3/4″ and 1-1/2″; Flange: UNI DN80…DN150; Mounting bracket |

| Max. measurement distance | 50 m (164 ft) |

| Communication | 4…20 mA HART Additional analog or switch output PROFIBUS PA PROFINET with Ethernet-APL Bluetooth® wireless technology and app (optional) |

| Certificates / Approvals | IEC Ex, ATEX, CSA C/US, EAC Ex, JPN Ex, KC Ex,INMETRO Ex, NEPSI Ex, UK Ex |

| Safety approvals | Overfill protection WHG; SIL 2 |

| Design approvals | Acceptance test certificate 3.1, EN10204; Declaration of Conformity ASME B31.3; AD2000; PMI test; CRN approval |

| Hygienic approvals | EU Food Contact Material (EC) 1935/2004; US Food Contact Material FDA CFR 21 |

| Marine approval | ABS, LR, BV, RINA, DNV |

| Options | Display, Customized settings, App ‘SmartBlue’ for commissioning and operation via Bluetooth Gas-tight implementation; Overvoltage protection; PWIS free |

| Application limits | Process temp. <-40°C (-40°F) or > 200°C (392°F) -> FMR62B Very aggressive media -> FMR62B Turbulences, stilling well and bypass -> FMR62B Strong foam and interfaces –> FMP5x |

Write your message here and send it to us.