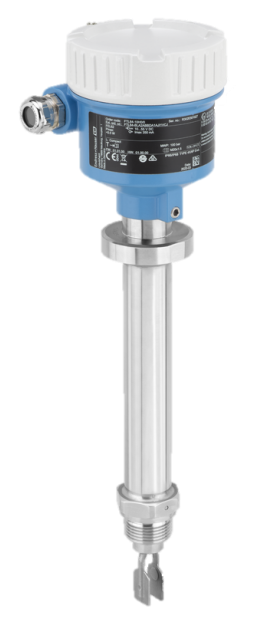

E+H Tuning Fork Level Switch

Tuning fork limit switches are the first choice for many applications:

Zero maintenance: no moving parts, corrosion-resistant, can withstand a certain degree of adhesion

Versatile: not affected by changes in media properties, disturbances, bubbles, foam, vibrations, solid media, process temperature and process pressure changes

FTL51B – Intelligent limit switch

Limit switch and density measurement (with FML621 density computer)

Developed according to IEC 61508, up to SIL2 and SIL3 (redundant structure)

Proof Test via external button (Proof test wizard can be executed via DTM or E+H App)

Heartbeat technology diagnostics, verification and monitoring functions via E+H SmartBlue App (Bluetooth technology)

Heartbeat monitoring allows trend analysis (e.g. tuning fork vibration frequency trend)

Integrated sensor and extension rod sensor

International standards for intrinsic safety and explosion-proof certifications

Visual status indication (optional LED light)

Process conditions -60℃~150℃, 100bar

Ambient temperature -60℃~70℃

Material: Nace MR0103/ MR0175/AD2000 conform

Safety design by ASME B31.3

FTL51B intelligent limit switch has added some new functions that can provide added value to customers.

Liquiphant FTL62 – Tuning fork with coating for corrosive media

Various coatings – ECTFE, PFA (EdlonTM/Ruby Red/conductive), Enamel for corrosive media

Highest safety – developed according to IEC 61508 SIL2/3 Redundant configuration up to SIL3

Easy Proof test – via SmartBlue-App wizard menu

Heartbeat Technology – self-diagnosis, self-calibration, self-monitoring in SmartBlue-App

Heartbeat monitoring: trend analysis è tuning fork vibration frequency trend

Tuning fork action point: one-piece or extension rod, you can choose

Optional NEPSI explosion-proof certification and CCC explosion-proof certification

Liquiphant FTL64 – for high temperature and high-pressure applications

Liquiphant FTL64 is the best choice for high-temperature liquid limit level detection, easy-to-perform instrument functional safety testing, and reliable operation, according to IEC 61508 safety standards (SIL), API 2350 standards, and WHG standards. The tuning fork is designed based on the active safety principle to meet the requirements of high-temperature medium limit detection, reliably monitor the liquid level, prevent overflow, and provide pump dry protection. FTL64 is easy to use, comes with a digital interface, and real-time data is at your fingertips

Expert in high-temperature and high-pressure applications

Temperature resistance -60°C to 280°C, maximum pressure resistance 100 bar

High safety – Based on IEC 61508 SIL2/3 development, the redundant configuration can reach the safety level that meets SIL3

Safety testing is simple and easy – menu-guided operation through SmartBlue-App

Heartbeat technology – use SmartBlue-App to achieve self-diagnosis, self-calibration, and self-monitoring

Heartbeat self-monitoring – trend analysis, which can analyze the trend of the resonant frequency of the fork body

PFA coating has a maximum temperature resistance of 230℃ and a pressure resistance of 40 bar

Suitable for different switch measurement points – compact or extended rod type

The second line of protection – gas-tight feedthrough

Various explosion-proof certification requirements