Glass Plate Level Gauge

Glass Plate Level Gauge, also known as Sight Type Glass Level Gauge.

The Glass Plate Level Gauge is a critical device widely used in multiple industries to monitor and measure liquid levels inside tanks, vessels, and containers. Available in three main variants—transparent, reflex, and sight glass—this gauge ensures clear visibility and precise readings, improving both operational safety and efficiency.

How it works:

- The gauge is connected to the tank via top and bottom ports, creating a continuous flow path for the liquid.

- The liquid level inside the gauge aligns with the liquid level in the tank, providing a visual indication.

- This direct reading system is based on the hydrostatic principle, where the liquid seeks its level.

Types of glass plate level gauges:

- Transparent: Used for clear liquids, allowing for direct observation.

- Reflex: Features grooves on the glass that create a prism effect, making the liquid and vapor spaces appear different colors for easier reading.

- Sight glass: A general term for gauges that allow visual observation of the liquid level.

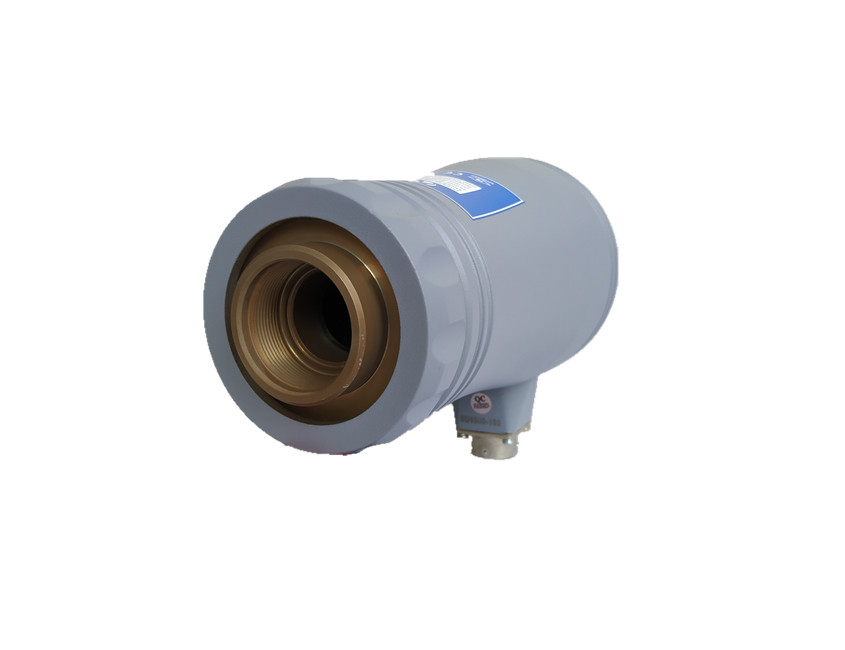

Reflex Level Gauge

Technical Parameter

- Measuring range: 300–2000 mm

- Working pressure: ≤ 10 MPa

- Working temperature: -20 °C to 450 °C

- Visible range: 100 mm – 300 mm per section

- Chamber material: carbon steel, stainless steel, titanium

- Glass material: toughened high borosilicate glass, quartz glass, aluminosilicate glass

- Connection: thread, flange, clamp, welding

- Display: single color, double color (air displays red and water displays green)

Transparent Level Gauge

Technical Parameters

- Measuring range: 300–3000 mm

- Working pressure: ≤ 22 MPa

- Working temperature: ≤ 550 °C

- Visible range: 100 mm – 300 mm per section

- Chamber material: stainless steel 301, 316L, carbon steel

- Glass material: borosilicate glass, aluminosilicate glass, quartz glass

- Transparent level gauge structure and components Connection: flange, thread

- Surface treatment: galvanized, lacquer finish

- Display: single color, double color (air displays red and water displays green)

Applications:

- Monitoring liquid levels in tanks and vessels: Crucial for maintaining optimal levels in various industrial processes.

- Ensuring safe and efficient operations: Helps prevent overfilling, dry running, and other potential issues.

- Suitable for a wide range of industries: Including chemical, oil and gas, power generation, and food and beverage.

When to Choose a Glass Plate Level Gauge?

A glass plate level gauge is an ideal choice in scenarios where: Direct, real-time observation of liquid levels is essential.

Cost-effective and simple solutions are required.

The liquid is transparent or semi-transparent.

Operating conditions include moderate to high pressure and temperature.

Maintenance Tips

To ensure long service life:

Regularly clean the glass to prevent sediment buildup.

Inspect seals and gaskets for wear and replace them when needed.

Use appropriate safety measures to handle glass under pressure.