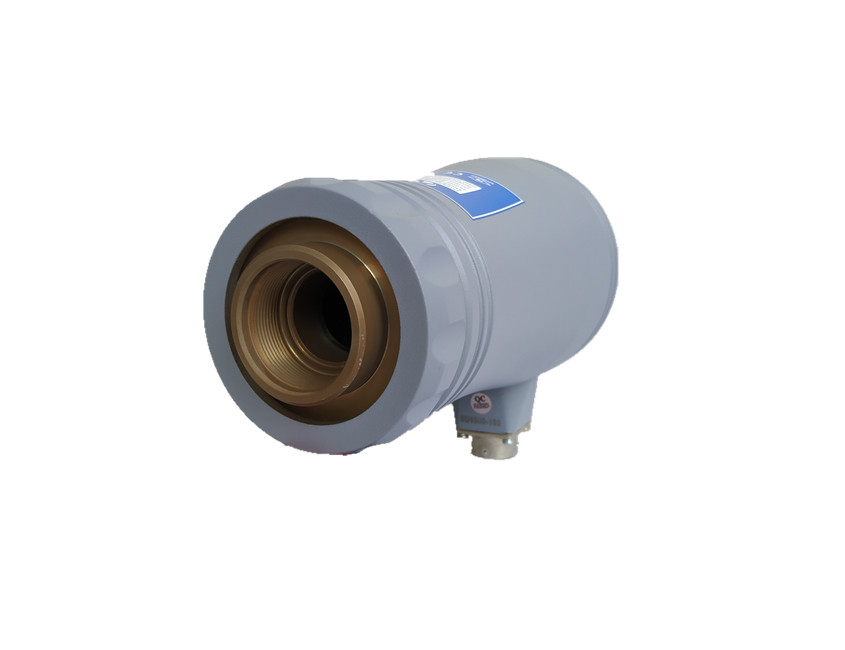

PVTVM TM500 Series Intelligent Digital Transformer Protection Meter

TM500 series intelligent digital transformer protection meter is a fully digitalized intelligent transformer protection meter developed by PALIS in the United States based on inheriting the advantages of TM series single-channel transformer protection meter, summarizing the experience of vibration protection for many years, and applying the latest achievements in the field of information processing technology. At the same time, it can be comparable to a multi-channel monitoring meter when composed of multiple modules.

TM500 series intelligent digital transmission protection meter combines the characteristics of vibration protection meter, vibration transmission meter and vibration switch into one. TM500 series protection meter adopts modular design, each module can carry out vibration monitoring individually, providing all the on-site configurations, controls, inputs and outputs of single-channel protection meter, meanwhile, the user can choose multiple modules to form a vibration monitoring and protection system according to the needs. In addition to 4-20mA analog output, TM500 also provides digital output, two-stage relay alarm output and status monitoring output, which greatly improves the system’s analysis and monitoring capabilities.

TM500 series intelligent digital transformer protection meter meets API670 standard. Adopting full digital signal processing and built-in digital preamplifier, it is compatible with any manufacturer’s sensor system and has flexible programmable characteristics and high reliability.

The TM500 series of intelligent digital transformer protection meter adopts a reliable microprocessor and a number of redundant designs, while the system has self-diagnostic functions, thus maximizing the reliability of the instrument.

Module self-test – TM500 module is equipped with power-on self-test and periodic self-test during operation, which monitors the sensor status, power supply voltage, field bus status and sends out fault alerts through LEDs and data bus.

System management – TM591 can carry out online automatic inspection for all TM500 modules in the system, monitor the OK status of the modules in real time, record the alarm events, display the fault information and alarm information on the spot, and drive the relay to alarm the system fault.

TM591 can automatically inspect all TM500 modules in the system online, monitor the module OK status in real time, record the alarm events, display the fault information and alarm information on the spot, and drive the relay to alarm the system fault.

Redundant Outputs – The TM500 module has two levels of redundant relay alarm outputs.

Optical isolation – The power supply, signal processing circuits and relay output circuits of the TM500 module are all optically isolated. It greatly improves the anti-interference ability of the system and improves the signal quality.

System Integration Management – TM591

System real-time monitoring and management – Online real-time monitoring and management of all TM500 signal processing modules in the system, real-time monitoring of module status.

System Accident Memory – Record alarm events, display fault information and alarm information on the spot, and drive the OK relay to alarm system faults.

System integrated display – real-time display of the operating status of each channel, measured values, alarm status, etc.. And can display the historical event records.

System integrated control – integrated control system reset, doubling, bypass, etc.. Integrated digital port

Configuration and Calibration – The TM591 can be configured and calibrated separately for each module in the system. The all-digital display simplifies the configuration and calibration process. Digital Condition Monitoring – The TM591’s Modbus-TCP interface allows interconnection with condition monitoring software.

Digital Condition Monitoring – Through the Modbus TCP interface, the TM591 can be interconnected with condition monitoring software to transmit static parameters (trend, real-time value, alarm status, gap voltage value, system OK status) or dynamic parameters (waveform, spectrum, key-phase signals, waterfall diagram) to analyze the system operation status.

Monitoring Unit Type

Turbine

Compressor

Motor

Pump

Fan

Blowers

Centrifuges

Generators

Turbo compressors

Technical indicators

Electrical specifications

External power supply: +24VDC: 20-30VDC, @150mA; Isolated voltage: 1000VDC

+24VDC: 20-30VDC, @150mA; Isolated voltage: 1000VDC

220/110VAC: 90-250VAC @50mA; Isolated voltage: 2500VAC

Frequency Response (-3dB).

Standard Frequency Response: 2 ~ 4.0KHz

Low Frequency Option: 0.5 ~ 100Hz

External Eddy Current Probe

Sensitivity: 5mm and 8mm

5mm and 8mm probes: 8 mV/μm (200 mV/mil)

11mm probe: 4 mV/μm (100 mV/mil)

Buffered Output.

Buffered output of raw signal, unfiltered

Output impedance: 150Ω

Maximum transmission distance: 300 meters (1000 feet)

Sensitivity: same as sensor

Terminals: Field BNC and remote terminals

4-20mA Output.

4-20mA active output (no loop power required)

Maximum Load Impedance: 380Ω

Alarm Settings

Range: 0 ~ 100% full scale

Accuracy: ±0.1%.

Alarm Relay

Sealing: Epoxy

Node Capacity: 0.2A/240VAC, 0.4A/110VAC or 2.0A/24VDC, resistive loads

Node Type: Single-pole, double-throw

Isolation Voltage: 1000VDC

LED operation status indicator: OK (green)

OK (green): lighted when the system self-test passes normal operation, otherwise off; short time flashing when communicating with TM591.

ALM (red and yellow lights): yellow light indicates alarm; red light indicates interlocking

BYP (red): system bypass indication

Alarm Reset/Alarm Bypass.

Panel key reset and remote reset/bypass terminals

TM591 key reset and TM591 remote alarm reset/bypass terminals

Digital Condition Monitoring Functions

Alarm Data: The TM500 can store up to 100 alarms.

Trend Data: The TM500 can store up to 1000 trend data.

Spectrogram: up to 800 spectral lines

Environmental Specifications

Operating Temperature: -30°C to +70°C

Storage Temperature: -40℃~+100℃

Humidity: 90% non-condensing

Housing: Aluminum

Modular Units

The TM500 series has modular units with different functions:

TM531/TM532/TM535: Eddy current sensor module (built-in preamplifier)

Eddy current sensor module capable of measuring radial bearing vibration, axial displacement, rotational speed/key phase, etc.. Can be used with a variety of eddy current sensor systems to form a monitoring system (including sensors from other companies).

Key features:

Built-in preamplifier module, no need for additional preamplifiers.

Compatible with other eddy current sensor systems.The TM531/TM532/TM535’s field linearization feature allows the module to be connected to virtually any eddy current sensor system. This feature can greatly reduce the number of spare modules.

Rotors of various materials can be monitored: steel, tungsten, copper-nickel alloys, etc. (calibration of the characteristic curve of the eddy current sensor system is required).

TM521/TM522/TM525: Eddy current sensor modules (external preamplifier)

Eddy current sensor module capable of measuring bearing radial vibration, axial displacement, rotational speed/key phase, etc. Can be used with a variety of eddy current sensor systems to form a monitoring system (including sensors from other companies).

Main features:

The TM521/TM522/TM525 series are external preamplifier modules.

Can monitor rotors of various materials: steel, tungsten, copper-nickel alloys, etc. (need to calibrate the characteristic curve of the eddy current sensor system)

TM511 Casing Vibration Monitoring Module

Primarily measuring acceleration, velocity or displacement of casing vibration, the TM511 can be used with a variety of casing vibration sensors to form a monitoring system (including sensors from other companies):

Acceleration sensors

Velocity sensors

TM591 System Integration Module