Flame Monitor

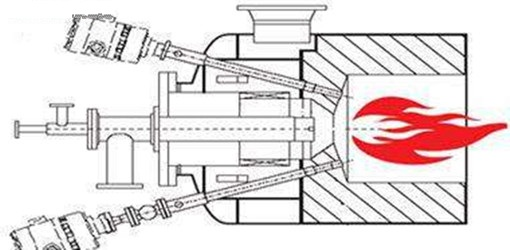

Flame monitors, also known as electric eyes, are used to monitor the flame status of the burner and send “flame present,” “flame out,” or “interrupt signal” to the control system. A device, generally composed of sensors and controllers. It is the key detection equipment in the automatic control of an industrial furnace to ensure the safe operation of the furnace.

Fire detection is the boiler’s “eyes,” its role throughout the entire process from the start of the boiler to full load operation. When the whole furnace fire or burner flames out, the fire detection alarm signal is issued, and the system issues an interlock signal to stop the fuel supply to prevent the accumulation of fuel in the furnace caused by the occurrence of a boiler explosion.

Introduction to the furnace flame monitor:

Detection Principle

The combustion of oil, coal, or gaseous fuels is, in essence, the release of fuel chemical energy in the form of electromagnetic waves, and the spectra emitted by the combustion intermediates of different fuels are not the same. The photoelectric sensor in the fire detection probe, after receiving the emitted spectra of different wavelengths, delivers the flame detection signal to the boiler management system or combustion controller through solid-state signal processing technology.

>Fuel oil flame: contains a large amount of infrared, some visible light, and a small amount of ultraviolet; pulverized coal flame: contains a small amount of ultraviolet, abundant visible light, and infrared; Gas flame: contains an abundance of ultraviolet and infrared and a small amount of visible light.

>Ultraviolet flame monitor: the use of an ultraviolet photosensitive tube to receive ultraviolet light emitted by the flame, converted to electrical signals, processed by the controller output control instructions.

>Conductive electrode flame monitor: insert a heat-resistant steel electrode into the flame and apply voltage, and detect the current signal in the flame to determine the flame state.

Flame detector classification

According to the detection element distinction, they can be divided into infrared (IR) type, ultraviolet (UV) type, and visible light type. According to the fire detection structure, it can be divided into integrated fire detection and probe & amplifier split fire detection. According to the installation mode distinction, it can be divided into fiber-optic type (internal peeping) and observation tube type (external peeping). In addition, according to the special requirements of the industry, there is a distinction between the explosion-proof type EX and the non-explosion-proof type.

Ultraviolet flame monitor: sensitive to ultraviolet light of 180-260 nm wavelength, suitable for flame detection of hydrocarbon fuels such as gas, fuel oil, etc., characterized by high sensitivity and fast response speed.

Conductive electrode type flame monitor: based on the flame conductive principle, suitable for contact detection, by detecting the current signal in the flame to determine the flame status.

Function

Monitors the presence or absence of flame and sends a signal to the control device in time to take corresponding measures when the flame is extinguished, such as shutting down the fuel supply to prevent accidents.

Composition

Generally consists of a sensor and a controller. The sensor is responsible for detecting the flame signal, and the controller processes the signal and outputs control commands.

Installation and commissioning

When installing the sensor, it is necessary to align the sensor with the flame to ensure that the line of sight is not blocked and adjust the monitoring distance according to the intensity of flame radiation and the size of the detection channel.

When debugging, make sure that the sensor and controller are connected correctly, and adjust the sensitivity according to the site conditions to avoid false alarms or missed alarms.

Precautions

Clean the sensor lens regularly to prevent dust or dirt from affecting the detection effect.

Ensure that the sensor working environment temperature is within the specified range to avoid excessive temperature damage to the equipment.

For contact monitors, pay attention to the heat-resistant bearing capacity of the electrode to avoid damage due to high temperature.

A furnace flame monitor is important equipment to ensure the safe operation of an industrial furnace. Choosing the right type of monitor and installing and debugging it correctly to improve the safety and stability of furnace operation is of great significance.