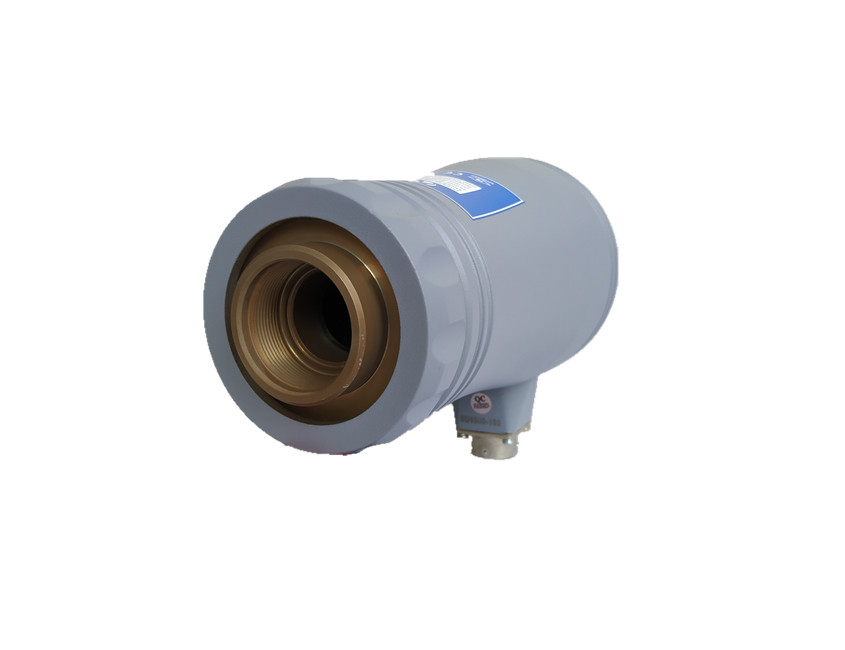

Bimetallic Temperature Gauges

Temperature Gauge

A temperature gauge is a device designed to measure and display the temperature of a particular system or environment. Whether in automotive, industrial, or scientific settings, these instruments help ensure that processes are running within safe and efficient temperature ranges. Temperature gauges play a crucial role in various industries, offering invaluable insights into thermal conditions for optimal performance and safety.

Types of temperature gauges:

- Bimetallic Temperature Gauges: Use two metals with different thermal expansion rates; temperature changes cause bending, moving a pointer to indicate temperature.

- Liquid Filled Thermometer:A liquid (e.g., glycerin or silicon oil) in a glass tube expands/contracts with temperature, showing readings on a scale—often used as a mercury alternative.

- Gas (Expansion) Thermometers:Measure temperature via gas pressure/volume changes, preferred in high-precision scientific applications.

Key Features of Temperature Gauges

Temperature gauges are designed with various features to ensure accuracy, durability, and versatility across different applications:

- Customizable Range– Measure specific temperature ranges for diverse uses.

- High Precision– Critical for industries needing exact temperature control.

- Fast Response Time– Essential for monitoring rapid temperature fluctuations.

- Robust Construction– Resistant to corrosion and harsh conditions for long-term reliability.

- Flexible Installation– Multiple mounting options, display types, and connection choices.

- Alarm Functions– Alert users when temperatures exceed set limits.

- Calibration & Remote Monitoring– Ensures accuracy and allows real-time data access.

- IP Ratings– Protection against dust and water for use in challenging environments.

Applications of Temperature Gauges

Temperature gauges are vital in many industries for monitoring and controlling temperature conditions:

- Oil and Gas Industry: Monitor temperatures in drilling, refining, and transportation processes for safety and efficiency.

- Manufacturing & Processing Industries – Ensures optimal material temperatures for quality and efficiency.

- Energy Production & Power Plants– Tracks component temperatures for safe and efficient operation.

- HVAC Systems– Maintains comfortable and energy-efficient indoor climates.

- Automotive Industry – Monitors engine temperature to enhance performance and durability.

- Aerospace & Defense– Monitor thermal conditions of critical components in aerospace applications for safety and reliability.

- Environmental Monitoring– Studies temperature changes in ecosystems and climate research.

- Plastics & Rubber– Control temperature during molding, extrusion, and curing processes for desired material properties.

- Electronics and Semiconductor Manufacturing: Ensure precision temperature control for the reliability and performance of electronic components in manufacturing.

Write your message here and send it to us.