GE DigitalFlow™ GF868 Ultrasonic Flowmeter for Flare Gas

DigitalFlowTM GF868 Ultrasonic Flow Meter for Flare Gas

GE Industrial Sensing & Measurement’s time-difference ultrasonic flowmeter uses patented, state-of-the-art signal encoding technology to provide accurate flow measurement for all types of liquids, flare gases, vapors, natural gas and flue gases, and other gases.

Panametrics Technical Advantages

Correlation time difference signal processing technology

Panametrics’s ultrasonic flowmeter, using its patented inter-correlation time difference signal processing technology, each flowmeter

Built-in special DSP digital signal processor, the multiple received signals for 64 superposition processing, greatly improving the signal-to-noise ratio, can measure other technologies can not be measured due to scaling of the inner wall of the pipeline, the outer wall of the rust or paint, poor flow conditions, the medium contains particles and other complex conditions of flow measurement, and even to solve the industry’s most difficult atmospheric pressure or micro-negative pressure gas flow measurement.

Sensor electroacoustic energy conversion efficiency

Thanks to decades of technology accumulation, Panametrics’ ultrasonic flowmeter sensor has a very high electro-acoustic energy conversion efficiency to ensure the effective propagation and conversion of the measurement signal. At the same time, the sensor are fully sealed structure, stable and reliable performance.

Signal tracking window

Panametrics ultrasonic flowmeter has a unique signal tracking window, can be in a wide range of automatic tracking because of the composition of the fluid medium or temperature and other reasons caused by the change in the velocity of ultrasound in the medium, without losing the signal.

Self-diagnostic function

Panametrics’s ultrasonic flowmeter not only has a self-diagnostic function, and the unique ultrasonic waveform display function can be very convenient and intuitive to determine whether the measurement status is good, to eliminate the complex conditions of the conventional signal strength and other diagnostic parameters difficult to identify the false signal state.

Industry firsts and patents

The first ultrasonic flow meter for flare gas (1982)

The patented technology of average molecular weight measurement has been the absolute leader in this field for more than 30 years, with a cumulative installed capacity of more than 7,000 units at home and abroad.

First Ultrasonic Flow Meter for Steam (1998)

Panametrics was the only manufacturer to introduce an ultrasonic flow meter for steam.

The first ultra-high/low temperature / high viscosity applications ultrasonic solutions (1995)

Patented waveguide beam transducer is the ultrasonic flowmeter highest and lowest temperature keeper (-200 to 600 ℃), is the only mature application of high-viscosity measurement technology

The first clamp-on ultrasonic gas flow meter (2001)

Thanks to its ultrasonic sensor, ultra-high electro-acoustic conversion efficiency and digital signal processing technology, become the clamp-on gas ultrasonic flow meter

Measurement of choice

The first ultra-high/low temperature clamp-on sensor technology (1996)

Measuring ranges from -200 to 400 °C from the first generation of OKS sensors to today’s second generation of C-ET sensors

Patented cross-correlation digital signal processing

Panametrics’ ultrasonic flowmeters can be used in the most difficult flow measurement applications, such as slurries with high solids content, low pressure, atmospheric pressure and even low temperature.

fluids such as slurries and other high solids content fluids, low pressure, atmospheric pressure and even negative pressure gas flow measurements.

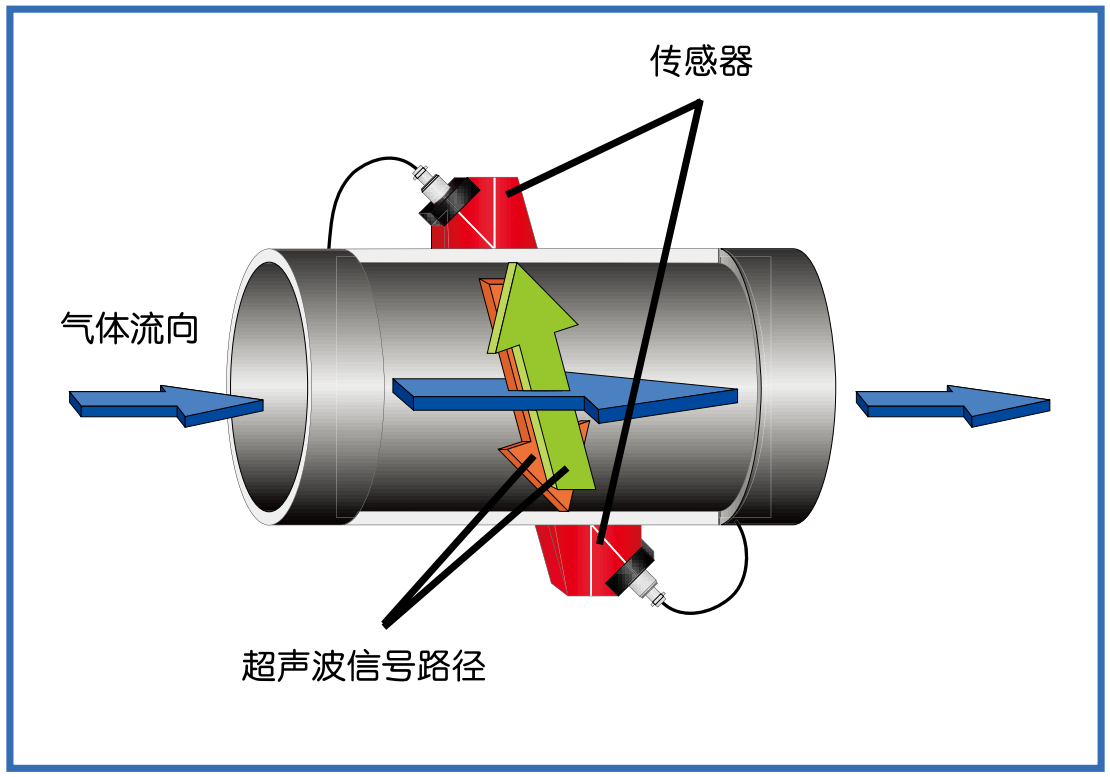

As the ideal technology for flare gas applications, ultrasonic flow measurement is not dependent on gas properties and does not interfere with the fluid flow. An all-metal ultrasonic transducer mounted on the pipeline emits pulses into the gas both upstream and downstream. Based on the difference in sound propagation time between the transducer and the countercurrent, the GF868 calculates the flow rate, volumetric flow rate and mass flow rate using advanced signal processing methods with the cross-correlation time difference method. If temperature and pressure values are entered, the flow meter can calculate the standard volume flow rate. For even higher accuracy, measurements can be made along two different measurement paths in the same pipeline using dual channels. The dual-channel version can also be used to measure two different pipelines or two different locations on the same pipeline.

Applications

The GF868 Gas Flow Meter is a proven ultrasonic flow measurement system that can measure:

Flare gases

– Detect and prevent losses due to leakage by measuring and identifying gas components.

– Can be used to estimate the overall plant capacity

– Reduce the proportionate amount of steam injected into the flare system through detection.

– Controls non-essential flare emissions, resulting in energy savings.

– Complies with authorities’ pollution controls

Emission Gases

Characteristics

Suitable for multi-component and variable gas measurements

Measures flow rate, volume flow, and mass flow

Measures the instantaneous molecular weight average

Measures hydrocarbon gases

No moving parts, no openings or tubing, accommodates contaminated and humid gases, and requires no routine maintenance

Provides accurate measurements regardless of gas composition

Can be used at both very low and very high flow rates

Proven mounting format for a wide range of applications

Built-in power supply for temperature and pressure transmitters

Range ratios up to 3940:1

New standard velocity range of 100 m/s (328 ft/s)

New extended speed range of 120 m/s (394 ft/s)

1 or 2 two-channel/path configurations

Patented Molecular Weight Measurement Technology

The GF868 utilizes a patent-protected method for calculating the average molecular weight of hydrocarbons. This unique method extends the range of average molecular weight measurements while greatly improving the accuracy and compensation of non-hydrocarbon gas measurements over previous methods. Accurate mass flow data and a more precise understanding of flare gas composition can enhance plant operational efficiency, enabling accurate measurement and control of vapor injection at the flare gas nozzle, rapid detection of flare gas leaks, early identification of process control hazards, and accurate balancing of plant materials.

Performance Indicators

Fluid type: Flare gas and vent gas.

Line Size: ANSI 2 in to 120 in (50 to 3000 mm)

Flow range: 0.3 to ±100 m/s.

Flow Rate Accuracy: Typically ±2-5% of reading.

Repeatability: ±0.2% to ±0.5% of reading

Range: 3280:1.

Power supply: Standard: 100~130VAC, 50/60Hz or 200~265VAC, 50/60Hz; Optional: 12~28VDC, ±5% .

Power consumption: ≤20W

Operating temperature: -10~55℃

Storage temperature: -40~70℃