News

-

How Pepperl+Fuchs Sensors Are Driving the Next Generation of Industrial Automation

As global manufacturing continues to move toward smarter and more connected systems, industrial sensors are playing an increasingly important role in improving efficiency, safety, and precision. Among the many technology providers in this field, Pepperl+Fuchs has become a well-recognized name for high-quality industrial sensing solutions. From proximity sensors to advanced identification systems, the company’s technologies are widely used in industries …Read more -

How to Choose a Reliable Instrumentation & Valve Supplier for Industrial Projects?

In industrial projects—whether in oil & gas, water treatment, power generation, chemical processing, or manufacturing—the selection of a reliable instrumentation and valve supplier is a decision that directly impacts system safety, operational efficiency, and long-term maintenance costs. Instruments and valves are not just components; they are critical control points that influence the stability and performance of the entire process. Choosing …Read more -

Accuracy and Stability Driving Industrial Progress GUANYA’s Perspective on Measurement and Control Instruments

In today’s industrial automation landscape, measurement and control instruments play a critical role in ensuring production efficiency, operational safety, and consistent product quality. Across industries such as oil and gas, power generation, chemical processing, water treatment, and manufacturing, the demand for accurate, stable, and reliable measurement data continues to grow. As a professional manufacturer in the field of industrial instrumentation, …Read more -

What Is a Flue Gas Expander and Why It Matters for Industrial Energy Recovery?

As global industries face rising energy costs and stricter environmental regulations, improving energy efficiency has become a strategic priority rather than a secondary consideration. Among the technologies gaining attention in heavy industry is the flue gas expander, a system designed to recover otherwise wasted energy from high-temperature, high-pressure exhaust gases. While often overlooked, this equipment plays an important role in …Read more -

Complete Guide to Cryogenic Valve Classification, Installation, and Maintenance

I. Introduction to Cryogenic Valves Cryogenic valves are not merely modified versions of standard valves but specialized equipment designed specifically for cryogenic operating conditions. According to international standards, valves operating below -40°C are classified as cryogenic valves, with those functioning below -100°C designated as deep cryogenic valves. These valves face challenges far beyond imagination: they handle highly demanding fluids such …Read more -

One Article to Quickly Grasp The Differences Between O-type and V-Type Ball Valves

O-type ball valves and V-type ball valves are two distinct ball valve types with different structural designs and functional focuses. They exhibit significant differences in engineering design, flow characteristics, regulating performance, and application scenarios: Structural Design: O-type ball valve: The ball features a circular through-hole at its center. When fully open, the through-hole diameter aligns with the pipeline’s inner diameter, …Read more -

Essential Explosion-Proof Knowledge for Instrumentation You Must Know

Fundamental Principles of Instrument Explosion Protection: Preventing explosions requires eliminating the simultaneous presence of all three conditions necessary for detonation: ignition source, combustible material, and oxidizer (oxygen). Since oxygen (air) is ubiquitous and difficult to control, the two most common explosion protection principles involve controlling explosive gases and ignition sources. Within the instrumentation industry, another principle exists: controlling the explosion …Read more -

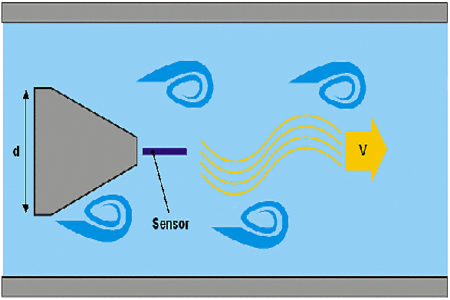

What Is a Flow Meter? A Comprehensive Guide to Flow Meter Classification and Working Principles

The flow meter is one of the most important instruments in industrial measurement. With the development of industrial production, demands for measurement accuracy and range have grown increasingly stringent, driving rapid advancements in flow measurement technology. To accommodate diverse applications, various types of flow meters have been developed. Currently, over 100 types of flow meters are in use. Flow meters …Read more -

Certified vs. Non-Certified Industrial Valve Suppliers: What’s the Real Difference?

When planning a new industrial project, selecting the right valve partner is often one of the most important decisions a procurement or engineering team will make. Valves directly influence system reliability, plant safety, and long-term maintenance costs. Yet one question frequently comes up during supplier evaluation: Do certifications actually matter? And if so, what really differentiates a certified industrial valve …Read more -

Top 10 Red Flags When Selecting an Industrial Valve Supplier for Your Project

Choosing the right industrial valve supplier can make or break a project. Whether you are building a new production line, expanding a power plant, or upgrading equipment in a chemical facility, the quality of your valves directly affects safety, uptime, and long-term operating costs. Yet many procurement teams still encounter delays, failures, and unexpected expenses because they overlooked critical warning …Read more