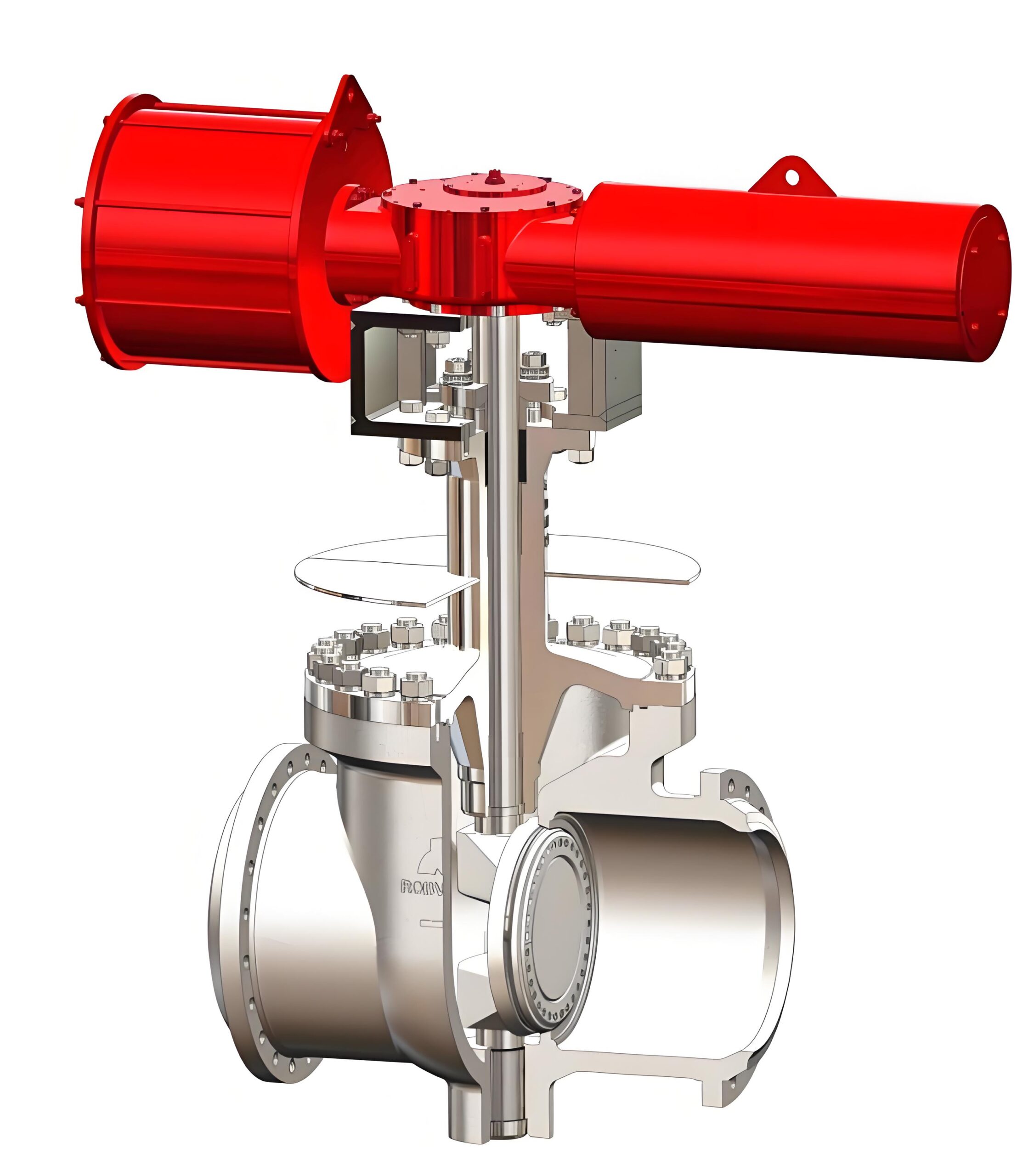

RobValve Cryogenic Triple/Quadruple Offset Valve

RobValve cryogenic triple/quadruple offset valve are specially developed for ultra-low-temperature conditions, mainly in the air separation, LNG and cryogenic ethylene industries. All-metal sealed, one-piece cast or forged bonnets. Body ports are available with flanges, butt welds, and lugs.

Size Size: 3“~240” (DN80~DN6000)

Pressure Class: Maximum ANSI CL2500

Temperature Temperature: Lowest to -254℃(-425℉)

A wide range of manual, electric and pneumatic actuators are available as options

All-metal seals are standard. The all-metal sealing method makes the sealing performance and torque and other operational properties independent of temperature changes.

The use of monolithic profiles or cast extension bonnets avoids weld leakage caused by asynchronous low-temperature shrinkage of the weld and the body.

A gas buffer zone is formed between the extended bonnet and the valve shaft, which restricts the low-temperature medium below the extended bonnet and keeps the packing away from the low-temperature medium to ensure the sealing performance of the packing so that the valve can operate normally.

The stem seal adopts low-leakage packing, which meets the requirements of ISO 15848-1, EPA Method 21, TA-Luft/VDI 2440 to ensure that the low-leakage requirements are met.

ROBVAVLE can be supplied with an extension bonnet for cold box applications.