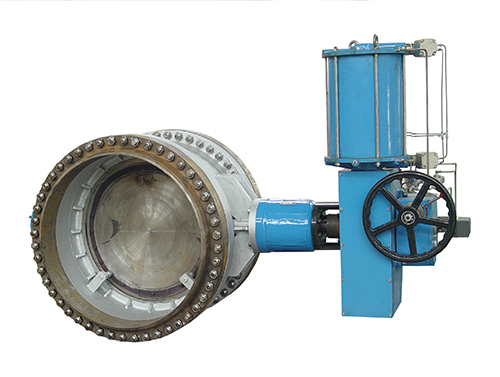

Triple Eccentric Hard-Sealed High-Temperature Butterfly Valve

Product Overview

The Triple Eccentric Hard-Sealed High-Temperature Butterfly Valve is a critical valve designed for regulating and isolating media within high-temperature pipelines in the refining industry. Engineered for extreme service, it excels in demanding applications with its superior performance in high-temperature resistance, wear and corrosion resistance, rapid actuation, high sensitivity, and zero leakage.

Key Features & Advantages

- Exceptional High-Temperature Performance: Reliably operates in environments with temperatures up to 750°C, maintaining structural integrity and sealing performance.

- Zero Leakage & Hard Seal: Features a triple-eccentric design with a hard metal seat, ensuring bubble-tight shut-off (ANSI B16.104 Class V) even after prolonged cycling.

- Abrasion & Corrosion Resistant: Specifically designed to handle erosive media such as high-temperature flue gas containing trace catalyst particles.

- Rapid & Precise Operation: Offers quick opening and closing action with high control sensitivity, ideal for precise flow regulation.

- Robust & Durable Construction: Built to stringent standards for long-term, maintenance-free service in critical refining processes.

Technical Specifications

| Parameter | Specification |

| Nominal Diameter | 300 ~ 2000 mm |

| Design Pressure | 0.3 ~ 0.6 MPa |

| Design Temperature | ≤ 750 °C |

| Operating Media | High-temperature flue gas, air, and other media containing微量 (trace) catalyst particles. |

| Sealing Standard | ANSI B16.104 CLASS V or higher |

| Primary Application | Regulation and isolation in high-temperature pipelines within炼油 (refining) and related process industries. |

Write your message here and send it to us.