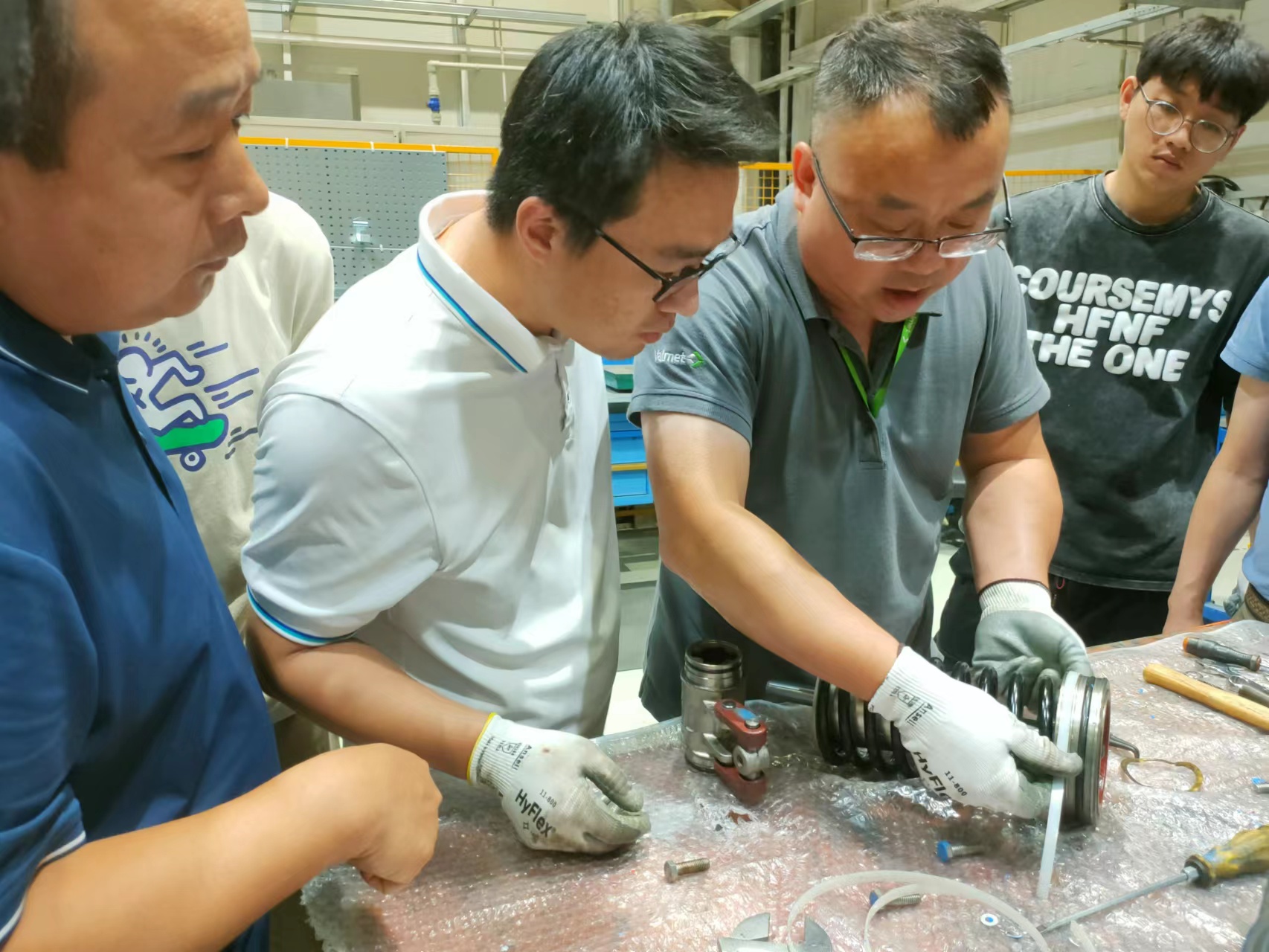

Valve Installation and Maintenance Training: Practicing the “Thinking for Others”

To continuously enhance the technical team’s professional capabilities and provide higher-quality support and services to our clients, Guanya Petrochemical recently organized a specialized training session on valve installation and maintenance in the workshop. This training not only focused on improving technical skills but also integrated the service philosophy of “Thinking for Others”, aiming to provide clients with more professional and efficient solutions.

Training Content

Valve Installation Specification:

The training detailed the installation procedures and operational standards for various types of valves (such as ball valves, butterfly valves, and control valves), ensuring that team members master installation techniques and reduce potential issues during equipment operation.

Debugging and Troubleshooting:

Through simulated real-world scenarios, the team learned valve debugging and troubleshooting methods, enhancing their ability to resolve complex issues and ensuring efficient operation of client equipment.

Maintenance and Upkeep:

The training also covered valve repair techniques and daily maintenance knowledge, enabling the team to provide comprehensive technical support and extend the service life of equipment.

Service Philosophy: Thinking for Others

Guanya Petrochemical has always adhered to the service philosophy of “Thinking for Others”, starting from the actual needs of clients to provide tailored solutions. This training not only improved the team’s technical capabilities but also strengthened their service awareness, ensuring that every technician can think from the client’s perspective and deliver more considerate service.

Training Objectives:

This training not only enhanced the technical team’s professional skills but also further clarified Guanya Petrochemical’s service mission: “Client-Centric, Technology-Driven, Service-Guaranteed”. In the future, Guanya Petrochemical will continue to organize similar training activities to improve the team’s comprehensive capabilities and provide clients with higher-quality support and services.

Client Value:

By continuously improving the technical service level of valve installation and maintenance, Guanya Petrochemical is committed to helping clients achieve efficient equipment operation and smooth project execution. We believe that a professional technical team and the service philosophy of “Thinking for Others” will be the cornerstone of our clients’ trust in us.

Professional Service Resolves Valve Winter Freeze-up Issue at National Pipeline Network LNG Project

Professional Service Resolves Valve Winter Freeze-up Issue at National Pipeline Network LNG Project

Successfully Delivers Air Storage Tanks for Sonatrach’s MTBE Project in Algeria

Successfully Delivers Air Storage Tanks for Sonatrach’s MTBE Project in Algeria

Moore Industries PSD Programmable Scan Display In-Stock Inventory – Enabling Rapid Project Response

Moore Industries PSD Programmable Scan Display In-Stock Inventory – Enabling Rapid Project Response

China National Pipeline Tianjin LNG Phase II Project – SEVERN Valve and Actuator Commissioning & Maintenance, Supporting Energy Supply Security

China National Pipeline Tianjin LNG Phase II Project – SEVERN Valve and Actuator Commissioning & Maintenance, Supporting Energy Supply Security