China National Pipeline Tianjin LNG Phase II Project – SEVERN Valve and Actuator Commissioning & Maintenance, Supporting Energy Supply Security

Project Background

The China National Pipeline Tianjin LNG Phase II Project is a key national initiative for interconnected natural gas infrastructure and a vital component of China’s “Production-Supply-Storage-Sales” energy system. As a critical energy hub in North China, the project elevates the Tianjin LNG Terminal into the 10-million-ton annual capacity tier, with a gas supply capacity of 12 million tons/year, storage capacity of nearly 1 billion cubic meters, and a daily regasification output exceeding 70 million cubic meters—making it one of China’s largest and most powerful LNG terminals.

Challenges & Requirements

The reliability of critical valves and the precision control of actuators directly impact the safety and operational efficiency of LNG storage and transportation. The project demanded exceptional performance in sealing, cryogenic resistance, response speed, and long-term stability to ensure zero leakage and reliable operation under extreme conditions.

Our Solution

As an authorized service provider for SEVERN valves, our company played a key role in valve commissioning and maintenance for the Tianjin LNG Phase II Project. Our technical team collaborated closely with SEVERN engineers to deliver:

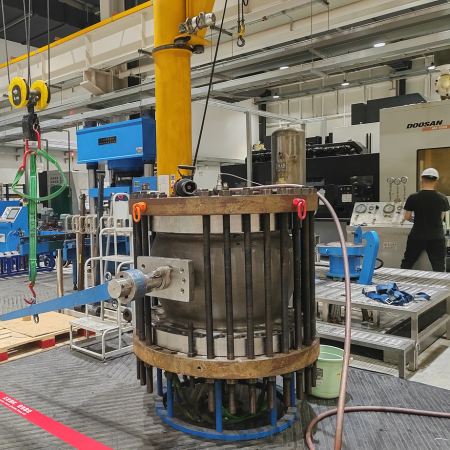

- Actuator Upgrades– Installed high-precision electric/pneumatic actuators tailored for ultra-low-temperature LNG applications, ensuring fast response and reliable operation.

- Valve Commissioning & Optimization– Conducted rigorous sealing tests, pressure trials, and automated system integration to guarantee performance under all operating conditions.

- On-Site Technical Support– Provided 24/7 emergency services to ensure on-schedule project completion and safe, efficient terminal operations.

Project Achievements

- Technological Excellence– SEVERN valves and actuators earned high praise from the client, setting an industry benchmark for LNG applications in China.

- Service Reliability– Our localized support team and rapid response capabilities ensured long-term operational stability.

Why Choose Us?

- Industry Expertise– Extensive experience in oil, gas, and LNG sectors, with over 50 major energy projects served.

- Technical Capability– Authorized distributor for top-tier brands like SEVERN, offering full lifecycle services from valve selection to maintenance.

- Customer Commitment– 24/7 support, customized solutions, and “zero-risk” operational assurance.

Contact Us

Looking for high-reliability valve and actuator solutions or professional support in LNG/petrochemical projects? Reach out to us for tailored products and services to ensure your project’s success!

Contact:

Tel: +86 0379-64613880

Email: sales@cnguanya.com

Website: https://www.chinaguanya.com/

Professional Service Resolves Valve Winter Freeze-up Issue at National Pipeline Network LNG Project

Professional Service Resolves Valve Winter Freeze-up Issue at National Pipeline Network LNG Project

Successfully Delivers Air Storage Tanks for Sonatrach’s MTBE Project in Algeria

Successfully Delivers Air Storage Tanks for Sonatrach’s MTBE Project in Algeria

Moore Industries PSD Programmable Scan Display In-Stock Inventory – Enabling Rapid Project Response

Moore Industries PSD Programmable Scan Display In-Stock Inventory – Enabling Rapid Project Response

V-Port Ball Valves Successfully Complete Factory Acceptance Tests, Ready for Delivery

V-Port Ball Valves Successfully Complete Factory Acceptance Tests, Ready for Delivery