What Is a Flue Gas Expander and Why It Matters for Industrial Energy Recovery?

As global industries face rising energy costs and stricter environmental regulations, improving energy efficiency has become a strategic priority rather than a secondary consideration. Among the technologies gaining attention in heavy industry is the flue gas expander, a system designed to recover otherwise wasted energy from high-temperature, high-pressure exhaust gases. While often overlooked, this equipment plays an important role in modern industrial energy recovery systems.

Understanding how a flue gas expander works—and why it matters—can help plant owners, engineers, and procurement teams make better decisions when optimizing performance and reducing operating costs.

What Is a Flue Gas Expander?

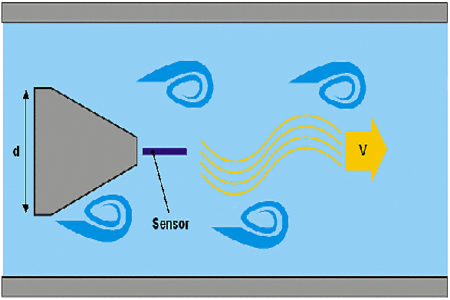

A flue gas expander is a mechanical device that converts the pressure and thermal energy of exhaust gas into usable mechanical or electrical energy. Instead of releasing high-energy flue gas directly into the atmosphere, the system allows the gas to expand through a turbine-like structure, producing power in the process.

This recovered energy is typically used to drive a generator, compressor, or auxiliary equipment, improving the overall efficiency of the industrial process without additional fuel consumption.

Unlike traditional steam turbines, flue gas expanders operate directly with exhaust gases, making them particularly suitable for facilities where high-temperature flue gas is a normal part of operation.

How Does a Flue Gas Expander Work?

In many industrial processes—such as power generation, cement production, metallurgy, and petrochemical refining—flue gas exits furnaces, reactors, or boilers at elevated pressure and temperature. This energy is often dissipated through pressure-reducing devices or dampers.

A flue gas expander replaces or complements these components. As the gas expands through the expander, its pressure drops, and the released energy is converted into rotational motion. This mechanical energy can then be transformed into electricity or reused within the system.

To ensure stable and safe operation, the expander system is usually integrated with high-temperature valves, flow control devices, and protection mechanisms that regulate pressure, temperature, and gas flow.

Why Flue Gas Expanders Matter for Industrial Energy Recovery

1. Improved Energy Efficiency

One of the most significant advantages of flue gas expanders is their ability to increase overall plant efficiency. By recovering energy that would otherwise be wasted, facilities can generate additional power without increasing fuel input.

This efficiency gain is particularly valuable in energy-intensive industries where even small percentage improvements translate into substantial cost savings.

2. Reduced Operating Costs

By producing usable energy from exhaust gas, flue gas expanders reduce dependence on external electricity sources. Over time, this can lead to noticeable reductions in operating expenses, especially in plants running continuous or high-load processes.

Additionally, integrating expanders can help stabilize pressure control systems, reducing mechanical stress on downstream equipment and lowering maintenance costs.

3. Support for Emission Reduction Goals

While flue gas expanders do not directly reduce emissions, they contribute to lower fuel consumption per unit of output. This improves the plant’s carbon intensity and supports compliance with energy efficiency and sustainability targets.

As regulations become stricter worldwide, energy recovery technologies are increasingly viewed as essential components of modern industrial systems.

Key Industrial Applications

Flue gas expanders are widely used in industries where high-pressure exhaust gas is readily available, including:

-

Power plants (especially combined cycle systems)

-

Cement kilns

-

Steel and metallurgy facilities

-

Chemical and petrochemical plants

-

Glass and building material production

In these environments, expanders are often integrated into waste heat recovery or pressure reduction systems to maximize energy utilization.

The Importance of System Integration

The performance of a flue gas expander depends not only on the expander itself but also on the surrounding system components. Valves, seals, piping, and control systems must be designed to withstand high temperatures, corrosive media, and fluctuating operating conditions.

High-performance industrial valves play a critical role in:

-

Regulating gas flow into the expander

-

Protecting equipment during startup and shutdown

-

Ensuring safe operation under abnormal conditions

Poor component selection can limit efficiency gains or lead to premature system failure.

A well-designed flue gas expander system relies heavily on reliable flow control components. High-temperature butterfly valves are commonly used to regulate flue gas flow before and after the expander, ensuring stable pressure and protecting the system during startup and shutdown. Selecting valves designed for extreme temperatures and fluctuating pressure conditions is critical for long-term operational stability.

What Engineers and Procurement Teams Should Consider

When evaluating a flue gas expander solution, decision-makers should focus on:

-

Operating pressure and temperature ranges

-

Gas composition and corrosion risks

-

Required power output and load stability

-

Compatibility with existing equipment

-

Long-term maintenance and service support

A successful installation requires close coordination between equipment suppliers, valve manufacturers, and system integrators.

Conclusion

Flue gas expanders are no longer niche equipment reserved for specialized plants. As industries strive to reduce energy waste and improve operational efficiency, these systems are becoming an increasingly important part of industrial energy recovery strategies.

By capturing the hidden value in exhaust gases, flue gas expanders help facilities lower operating costs, improve efficiency, and move closer to long-term sustainability goals. For companies planning system upgrades or new installations, understanding this technology is a key step toward smarter energy management.

If you are considering a flue gas expander system or upgrading related flow control components, sharing your operating conditions with experienced engineering partners can help ensure optimal performance and reliability.

Complete Guide to Cryogenic Valve Classification, Installation, and Maintenance

Complete Guide to Cryogenic Valve Classification, Installation, and Maintenance

One Article to Quickly Grasp The Differences Between O-type and V-Type Ball Valves

One Article to Quickly Grasp The Differences Between O-type and V-Type Ball Valves

Essential Explosion-Proof Knowledge for Instrumentation You Must Know

Essential Explosion-Proof Knowledge for Instrumentation You Must Know

What Is a Flow Meter? A Comprehensive Guide to Flow Meter Classification and Working Principles

What Is a Flow Meter? A Comprehensive Guide to Flow Meter Classification and Working Principles