Understanding the Different Types of Gate Valves

Gate Valves are typically classified in three ways.

- Types of Disk

- Solid taper wedge

- Flexible wedge

- Split wedge or Parallel disks Valve

- Types of Body Bonnet Joint

- Screwed Bonnet

- Bolted-Bonnet

- Welded-Bonnet

- Pressure-Seal Bonnet

- Types of Stem Movement

- Rising Stem or OS & Y Type (Outside Stem and Screw Type)

- Non-rising Stem type

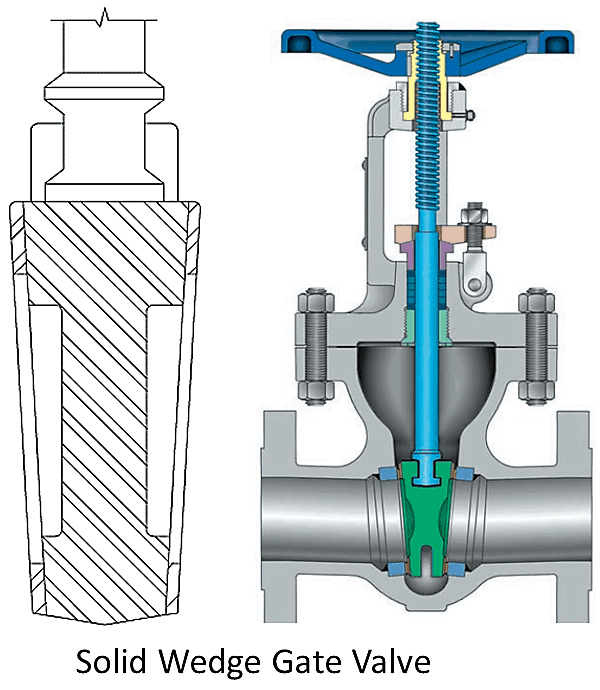

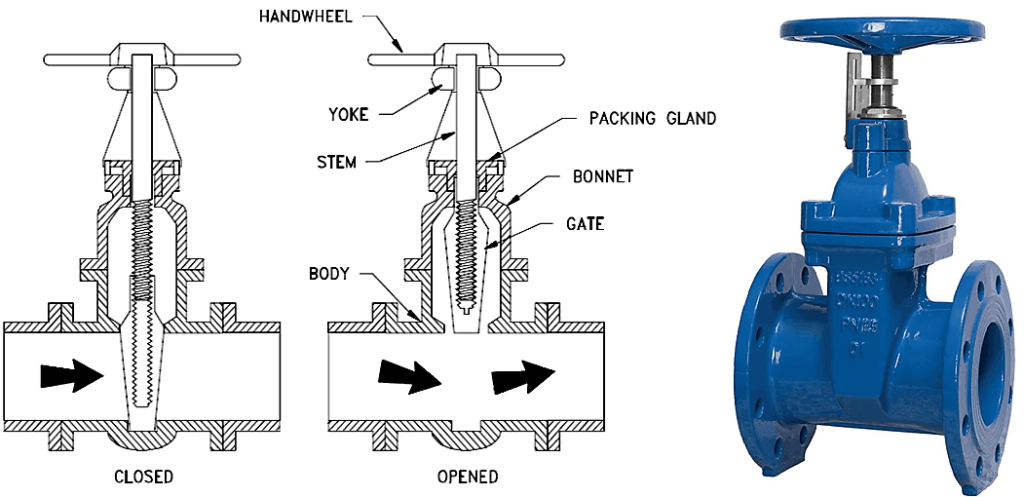

Solid Wedge Shaped Gate Valve

A solid wedge gate valve is the most common type due to its simplicity and strength. Suitable for almost all fluids, it can be installed in any position and handles turbulent flow. However, it doesn’t compensate for seat misalignment from pipe loads or thermal expansion, making it more prone to leakage. In high-temperature applications, it may suffer from thermal locking (a valve gate is stuck between the seats due to metal expansion).

Typically, it is used in moderate to low pressure-temperature conditions, it provides an unobstructed flow path when fully open. The gate, attached to the stem, moves up/down to control fluid flow.

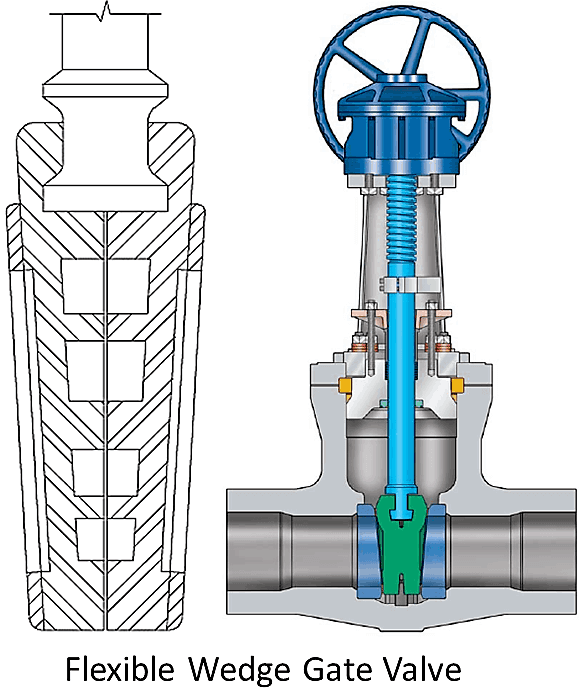

Flexible Wedge Gate Valve

A flexible wedge gate valve features a one-piece disk with perimeter cuts that vary in shape and depth. Shallow, narrow cuts retain strength but limit flexibility, while deeper, wider cuts enhance flexibility at the cost of strength.

This design improves seat alignment, offers better leak tightness to reduce leakage, and improves performance in situations where thermal binding is possible—ideal for steam systems, where pipeline expansion can distort valve bodies. The flexible gate adjusts to seat compression, avoiding jamming.

A key drawback is that fluid can accumulate in the disk, leading to corrosion and weakening over time.

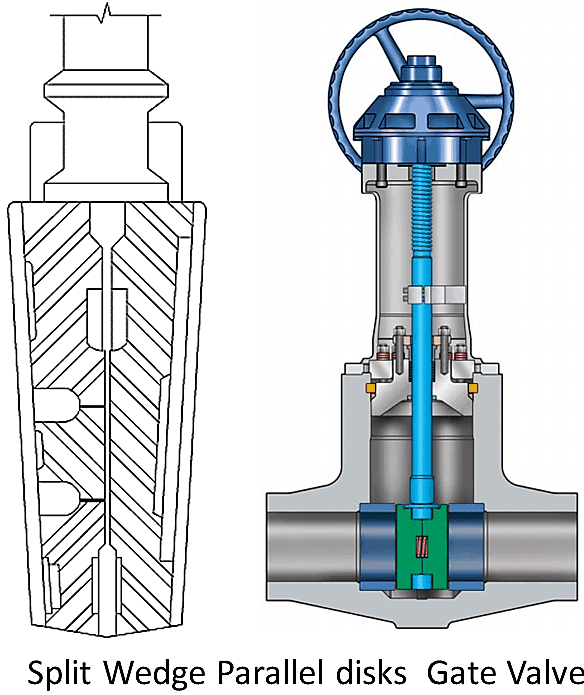

Split wedge or Parallel disks Gate Valve

A split wedge gate valve consists of two solid disk pieces held together by a special mechanism. If one half is misaligned, it can self-adjust to the seating surface. The disks can be wedge-shaped or parallel disk (spring-loaded for constant seat contact and bidirectional sealing).

The split wedge is ideal for non-condensing gases and liquids at normal or high temperatures. The disk freedom movement prevents thermal binding, even if the valve is closed when cold—ensuring no jamming occurs due to pipeline expansion when heated.

Types of gate valves based on the Body Bonnet Joint

- Screwed Bonnet– Simple and cost-effective, used for low-cost valves.

- Bolted Bonnet– Most popular design, uses a gasket to seal the body-bonnet joint.

- Welded Bonnet– Permanent connection, lighter than bolted types, ideal where disassembly isn’t needed.

- Pressure-Seal Bonnet– Best for high-pressure/temperature applications; sealing improves as internal pressure increases.

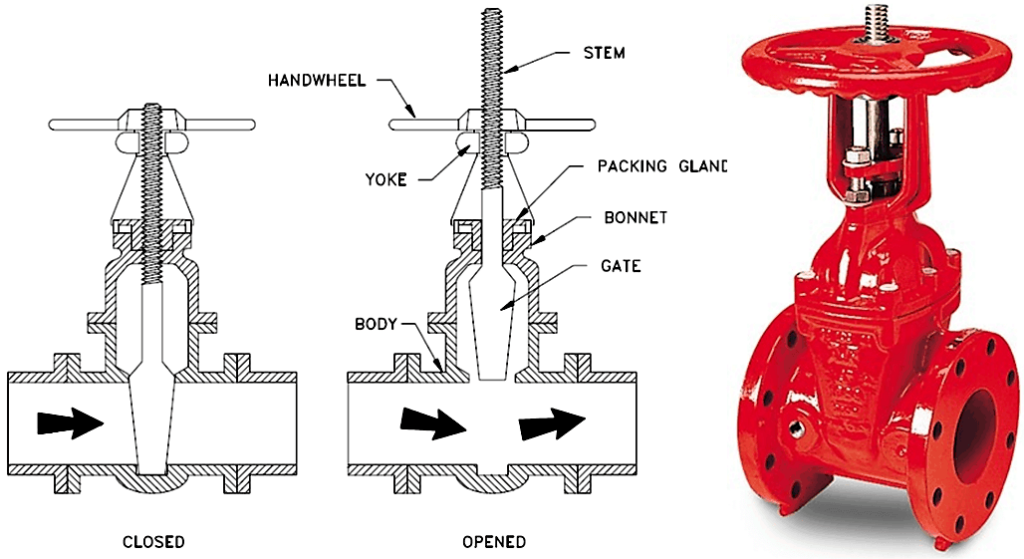

Types of Valves Based on Valve Stem Function

- OS & Y Gate Valve or Rising Stem (Outside Stem and Screw Type)

In a rising stem gate valve, the stem moves up when opening and down when closing, providing visual position indication. There are two types:

- Inside Screw Design– Threaded stem contacts the flow medium; the handwheel rises with the stem when opened.

- Outside Screw (OS & Y) Design– Only the smooth stem portion is exposed to the medium; the stem will rise above the handwheel. OS & Y means outside stem and York.

- Non-rising Stem Gate Valve or Insider Screw Valve

In a non-rising stem gate valve, the stem does not move upward. Instead, the threaded gate travels along the rotating stem like a nut. This design exposes the stem threads to the flow medium when closed.

This design is used where space is limited to allow linear stem movement, and the flow medium does not cause erosion, corrosion, or wear and tear to the stem material. This type of valve is also known as an insider screw valve.

Slide Gate Valves Market Overview (2025–2035)

Slide Gate Valves Market Overview (2025–2035)

What is a Gate Valve? Get a Full Understanding of This Common Gate Valve

What is a Gate Valve? Get a Full Understanding of This Common Gate Valve

Accuracy and Stability Driving Industrial Progress GUANYA’s Perspective on Measurement and Control Instruments

Accuracy and Stability Driving Industrial Progress GUANYA’s Perspective on Measurement and Control Instruments