What is a Gate Valve? Get a Full Understanding of This Common Gate Valve

Gate valves are essential components in controlling fluid flow across a wide spectrum of industrial applications.

Gate valves operate using a gate or wedge-shaped disc that moves perpendicular to the fluid flow.

It is a linear motion valve used to start or stop fluid flow. In service, the valve position is either fully open or fully closed gate.

When fully open, they provide minimal resistance to flow, making them ideal for applications requiring unrestricted fluid passage. Their straightforward design ensures reliable performance across diverse operational environments, contributing to their widespread adoption in critical infrastructure systems.

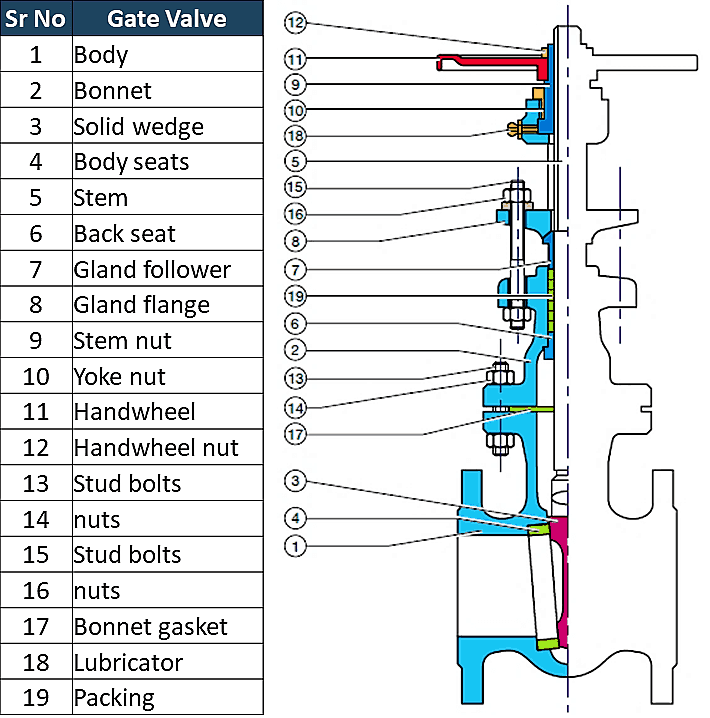

The Main Parts of The Typical Gate Valve:

- Body

- Bonnet

- Solid Wedge

- Body Seat

- Stem

- Back Seat

- Gland Follower

- Gland Flange

- Stem Nut

- Yoke Nut

- Handwheel

- Handwheel Nut

- Stud and Bolts

- Nuts

- Bonnet Gasket

- Lubricator

- Gland Packing

Types of Gate Valve:

1. Knife Gate Valves

- Key Features:

- Thin, sharp-edged gate design that slices through suspended solids

- Compact face-to-face dimensions for space-constrained installations

- Self-cleaning action during closure

- Available in unidirectional and bidirectional configurations

- Ideal Applications:

- Pulp and paper manufacturing, mining, wastewater treatment, food processing, chemical slurries

2 .Parallel Slide Gate Valves

- Key Features:

- Self-adjusting discs to handle thermal expansion

- Pressure-assisted sealing

- Reduced operational friction

- Suitable for horizontal and vertical installation

- Ideal Applications:

- Steam systems, power generation, refinery operations, district heating, industrial pipelines

3.Wedge Gate Valves

- Key Features:

- Mechanical wedging action for superior sealing

- Solid, flexible, and split wedge variants

- Resilient seat materials

- Bidirectional flow capability

- Wedge Types:

- Solid Wedge: Robust and general-purpose

- Flexible Wedge: Handles thermal variation

- Split Wedge: Accommodates seat irregularities

- Ideal Applications:

- Water distribution, fire protection, oil & gas, HVAC, industrial cooling

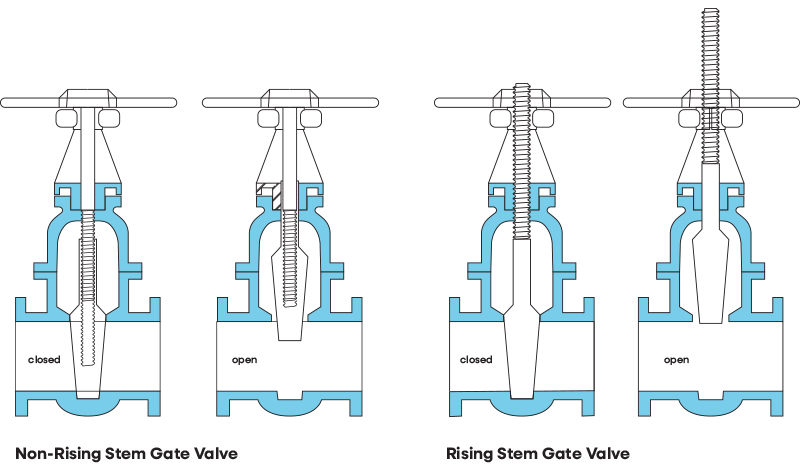

4. Non-Rising Stem Gate Valves

- Key Features:

- Rotating stem with internal gate threads

- Compact vertical profile

- Stem in contact with process fluid

- Optional position indicators

- Ideal Applications:

- Underground utilities, building interiors, confined mechanical spaces, retrofit projects

5. Rising Stem Gate Valves

- Key Features:

- External stem threads with visible movement

- Stem isolated from media

- Clear operational status indication

- Enhanced control accuracy

- Ideal Applications:

- Critical process control, clean rooms, corrosive media, hazardous materials, high-cycle systems

Gate Valve Used and Applications

- Gate valves are often used in almost all fluid services such as air, fuel gas, feedwater, steam, lube oil, hydrocarbon, and almost any services.

- Some special type is used in slurry and powder products also, such as knife gate valves.

- Metal seated gate valves are commonly used in high-temperature applications.

What is the advantage of a gate valve?

- The gate valve is designed to provide good shutoff

- The gate valve has no obstruction so the pressure in the valve doesn’t drop during operation and the loss is very minimal.

- Most of the gate valves can be used as bi-directional

- They are suitable for high-pressure and temperature applications and require less maintenance

What is the disadvantage of gate valves?

- It cannot be used to control the flow like globe valve and butterfly valve.

- It is slow in operation. Opening and closing take a good amount of time, also reducing the chance of hammering.

- When partially open, it creates vibration and noise.

- Repairs, such as lapping and grinding of seats are more difficult due to limited access.

These valves are versatile devices that find applications in a wide range of industries. The use of a specific type depends on the requirements of the application, the fluid or gas being controlled, and the operating conditions.

Slide Gate Valves Market Overview (2025–2035)

Slide Gate Valves Market Overview (2025–2035)

Understanding the Different Types of Gate Valves

Understanding the Different Types of Gate Valves

Accuracy and Stability Driving Industrial Progress GUANYA’s Perspective on Measurement and Control Instruments

Accuracy and Stability Driving Industrial Progress GUANYA’s Perspective on Measurement and Control Instruments